1. Introduction

Production and operation is an essential function for any firm. It is crucial for every firm, which might be either manufacturing or service firms. Operations management is concerned with managing the whole production and operation of the firm. It ensures how to produce or provide better service or products. All the activities and functions of a company depend primarily on the operational activities of the firm. Strategic planning and management are also closely related to the firm’s proper operations and production functions. The appropriate alignment between operations management and strategic planning is necessary for any firm to become successful. This paper primarily discusses the operational activities of the technology giant HP. Besides, strategic planning and management of the firm are critically analysed in this regard. The link and association between production and strategic planning are also analysed from the perspective of HP. Finally, some suggestions and guidelines are provided to the management of the firm.

2. Hewlett-Packard: A Brief Overview

Hewlett-Packard (HP) was founded in 1939 in Palo Alto, California, United States. It is a multinational information technology corporation owned by William “Bill” Redington Hewlett and Dave Packard, which became the world’s top PC seller in 2012. The firm is one of the leading IT giants operating in about 170 countries worldwide, and it’s product-line involves PCs, printers, networking, storage devices, equipment, servers, etc. IT and the outsourcing business processes, application development and management, systems integration, consulting, and other technology services are provided by its service unit. The company comprises six business units. It had a sales revenue of 120.357 billion with an operating income of 9.566 billion. It has an employee base of 320,000 in total. One of the significant events was its merger with Compaq in 2002.

3. The nature and Importance of Operation Management

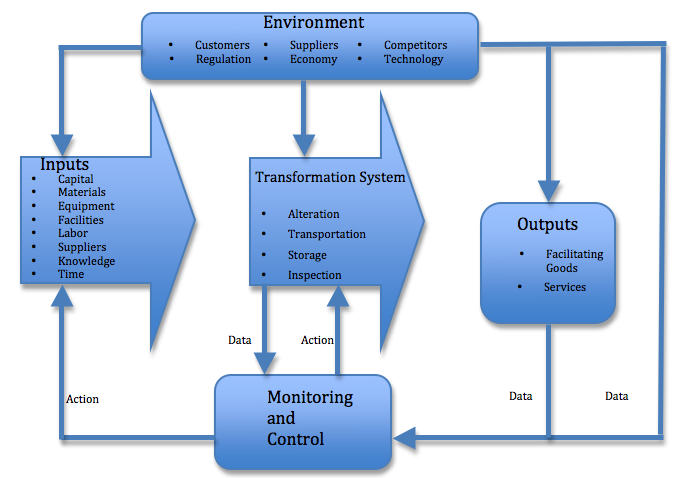

Operation management is the management of resources and processes related to the production of goods and services. The operation managers are responsible for supervising and managing the resources essential for producing goods and services (University, 2013). It is mainly related to the whole operation, such as an organisation’s production and delivery function (Toolkit.smallbiz.nsw.gov.au, 2013).

Following is a figure showing the process of transforming inputs into outputs carried out by the operations managers.

Importance of Operation Management

Operations Management (OM) is very much crucial for any business organisation. Without this function, no business can run smoothly and can achieve competitiveness. Following are some roles played by operations management:

- Recognising strategic objectives: Operations management helps determine the firm’s goals and develops a lucid vision of exactly how to attain them. It also transforms these objectives into propositions for the operating performance, purposes, speed, quality, reliability, flexibility and cost.

- Pursuing operational strategies: The active management seeks appropriate strategies for many decision-making in operations. In this regard, functional managers must maintain some guidelines to align with the organisational goals and objectives.

- Assisting the firm’s products and processes: Designing a product, service, or process involves shaping the material form, contour and composition of products.

- Planning and controlling: Operation management helps decide what the firm’s resources should do and how it should be done. The operational managers control the whole manufacturing operation.

- Improving the firm’s performance: The firm’s overall success depends on the excellent management of the firm’s operation. If the manufacturing and process are disrupted, the whole organisation will be affected.

Operations Management at HP

HP collects raw materials, supplies, and subassemblies from more than one supplier, but the firm depends solely on laser printing engines and supplies. The company gathers software and microprocessors from Microsoft and Intel, respectively. The company also has an association with AMD for microprocessors for a bit of requirement. (HP Annual Report, 2012). HP also maintains a relationship with several shipping firms that can provide more straightforward and low-cost supplies. That logistics function is organised to attain efficiency and effectiveness for better performance. (Hongni Zhang, 2010)

Most of the firm’s finished goods come from outsourced manufacturers around the world. This strategy is followed to pull off cost advantages and specialisation & learning effects on cost structure. The firm has original equipment manufacturers (OEMs) who manufacture products under the HP brand. HP pursues a small size of in-house manufacturing as it uses subassemblies operation and assemblies. This successful use of the production facility’s globalisation enabled the firm to earn an operating margin of about 8% in 2011, about 4% in 2003 (Wikinvest.com, 2013).

Operations Management and Strategic Planning

A process of a strategic business plan considers several factors to be in line with the firm’s objectives and vision. There exists a strong relationship between a firm’s operation management and strategic planning. The primary link is the budget of departments of the firm. The strategic plan provides a budget and forecast of future cost and income. The operational management gives a better idea about the forecasting to make it more accurate (Cigolini and Grillo, 2006). Proper resource allocation is another source of link between them. The strategic plan gives the appropriate equipment and resources needed to perform the best operation. On the other hand, operation management helps to do strategic planning. Performance management is another source of the relationship between operation management and strategic planning. Performance is managed in operation management based on set rules and targets by the strategic plan (Small Business – Chron.com, 2013).

4. The Link between Operations Management and Strategic Planning

In the case of HP, there is also a link between the strategic plan and operational management. The coordination between these plans is well thought and is helping the firm achieve competitiveness in the marketplace.

Economic, Efficiency and Effectiveness are the three E’s that are very important for any firm’s success. To achieve economy in the operation functions, HP pursued different strategies. The most important of them is the globalisation of production. Through this strategy, HP outsources its manufacturing from other parts of the world. This provides the firm with a cost advantage which leads to the economy. Outsourced manufacturers are basically from low-income countries, so that cost becomes as low as possible. Economies of scale are achieved through large scale production, and the market’s globalisation is vital for this. Efficiency is achieved through manufacturing the products from those who are experienced in the respective fields. For this, the learning effect is possible, which poses downward pressure on the cost structure. Effectiveness is doing the right thing, where efficiency is doing something right.

HP adopted many cost-reducing strategies to achieve cost leadership in the marketplace. Restructuring activities are being done within the organisation to affect cost minimisation. In addition to that, a significant change in salesforce was made to reduce the cost structure. The firm is trying to reform the supply chain, real estate strategy, stock-keeping units (SKU) etc., to implement the cost reduction strategy. The firm is also positioned adequately against the expected disruptions perceived by the strategic plan’s changes.

Objectives set by HP are dependent on the firm’s strategies used in operations and production functions. Due to shock in the market and economy, the firm faced some financial problems. This was due to the nature of the business and high capital expenditure. The structural change was also the reason behind this non-performance of objectives.

5. Organizing a Typical Production Process

Linear programming is a mathematical technique used to assist managers in planning and deciding appropriate trade-off of resources (Quizlet.com, 2013). This method can be used in HP to reduce the cost associated with the overall distribution of goods and services. The total labour hours can be minimised using this method while maximisation of profit is possible. Linear programming will also reduce the whole time needed to produce goods or services in the shortest possible time. The operation schedule can be set at that level where minimisation of production cost is possible.

CPM (Critical Path Method) and PERT (Programme Evaluation & Review Technique) are two crucial project management techniques. These methods help project managers sketch performing a whole task. Although they are similar in practice, there are some differences (Tutor2u.net, 2013). PERT is related to the event, while the CPM (Critical Path Method) is related to the activity. The activity is associated with the job and requires time which is denoted by arrows. On the other hand, an event is the beginning or end of a job and represented by nodes. No allowance is made for the uncertainties in the duration of time involved in the case of CPM based network analysis. Time is related to costs in CPM, which is not valid for PERT. In HP, both methods are used in different situations. And these two are needed and essential for the management of operations and other projects based works of the firm.

HP uses an operational plan and control mechanism, which is very much crucial for smooth operation. The firm uses different techniques and methods strategically. At first, it plans according to its targets of operational volume. The top managers determine the volume, and there is a separate board to make the proper analysis. Then the production and operation managers find their way to run the operation. After finishing the operation run, the respective managers controlled whether the outputs were according to expectation. HP is always trying to adjust its method of operation to changing needs of the market.

6. Application of Relevant Techniques to the Production

After analysing the operational techniques and process of the HP, some specific outcomes are apparent. The firm’s operation is being done to attain production efficiency. On-time production is also possible through the network management techniques of the firm. The outsourcing of production around the world keeps the cost at a minimum. The large scale of production is creating economies of scale, lowering the average cost structure of the firm. Due to the smooth run of output as per proper scheduling and controlling, the firm’s performance is good enough. Although the globalisation of production is possible, it enhances the risk level of the firm. The global economy hampers the whole business and activities of the operations. The ultimate impact of the above is operational efficiency.

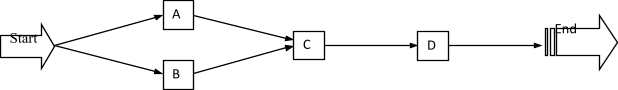

Here is the network path found by HP to manage the operation schedule. The production process starts with the pooling of materials from different sources. HP has contracted with sources of materials and supplies. Then these materials are forwarded to other outsourced manufacturers (denoted as A and B). The finished goods are transferred to a warehouse located in different locations (denoted as C). The products are then transferred to distributors and customers (denoted as D). The simple process stops here and can have a shape of the network as follows:

The world’s technology giant has appropriately positioned itself on the competitive edge. The firm is minimising the cost structure by outsourcing most of the manufacturing. At the same time, they are increasing the risk. The bargaining power of the suppliers may affect the overall strategy and profitability of the firm. The scheduled purchase orders and arrangements should be made so that price volatility does not occur.

7. Conclusions

For every firm, either manufacturing or service, operations management is very much important from many perspectives. To pursue a value-creating strategy, every firm needs to manage its production and operation function with greater efficiency. Inefficient management of operations may disrupt the whole processes of the firm. HP is properly trying out its unique manufacturing strategies to achieve market share and high response. Although the computer technology market is somewhat highly competitive, proper technique and operational management can make HP more sustainable.

8. References

University, C. 2013. HSC Online – Part 1 Role of operations management. [online] Available at: http://www.hsc.csu.edu.au/business_studies/operations/4407/Part%201%20Role%20of%20operations%20management.htm [Accessed: 21 Dec 2013].

Connexions. 2013. Operations management: The input/output transformation model. [online] Available at: http://cnx.org/content/m35439/latest/ [Accessed: 21 Dec 2013].

Toolkit.smallbiz.nsw.gov.au. 2013. Role of the Operations Manager. [online] Available at: http://toolkit.smallbiz.nsw.gov.au/part/13/63/260 [Accessed: 21 Dec 2013].

Hongni Zhang.2012. Research Hewlett Packard through its Value Chain. International Journal of Business and Management. Vol. 5, No. 8

Wikinvest.com. 2013. Stock:Hewlett-Packard (HPQ). [online] Available at: http://www.wikinvest.com/stock/Hewlett-Packard_(HPQ) [Accessed: 21 Dec 2013].

Hewlett-Packard Inc. 2012. Annual Report (2012). [report] Hewlett-Packard Inc.

Small Business – Chron.com. 2013. Links Between Strategic & Operational Plans. [online] Available at: http://smallbusiness.chron.com/links-between-strategic-operational-plans-17407.html [Accessed: 21 Dec 2013].

Tutor2u.net. 2013. Critical Path Analysis CPA (Network Analysis). [online] Available at: http://www.tutor2u.net/business/production/critical-path-analysis.htm [Accessed: 22 Dec 2013].

Quizlet.com. 2013. Operations Management Module B: Linear Programming. [online] Available at: http://quizlet.com/6331767/operations-management-module-b-linear-programming-flash-cards/ [Accessed: 21 Dec 2013].

Cigolini, R. and Grillo, G. 2006. How to Involve Operations Managers in the Strategic Planning Process. January. [report] R. Cigolini, G. Grillo,, pp. 2-7.